Freezers & Chillers: Selecting the Best Equipment For Your Food Production Needs

March 27, 2025For businesses in food storage and production, selecting the right freezers & chillers equipment is essential to ensuring quality and operational efficiency. From small bakeries to large food processing facilities, specific needs require specific solutions, and AFE offers a wide range of state-of-the-art freezing and chilling systems to suit diverse client demands. Whether you need to rapidly chill fresh food, freeze high volumes, or store ingredients with precision, having equipment tailored to your requirements can make all the difference.

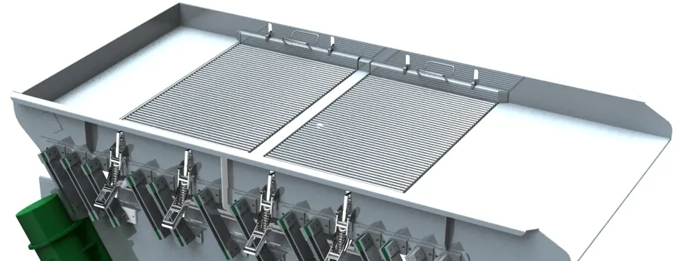

Shake It Off: AFE Shaker Units and How They Work

February 26, 2025Shaker units (vibratory conveyors) play an integral role in the industrial food production world. From ensuring product quality to optimizing operational efficiency, these specialized systems are key to handling food products effectively through various stages of the supply chain. At Advanced Food Equipment LLC (AFE), our shaker units are just one of the valuable solutions we provide to maintain seamless food processing, particularly in our Individual Quick Freezing (IQF) systems.

Built To Order: Customizing The Perfect IQF Freezer To Meet Your Needs

January 16, 2025Frozen food manufacturers and processors constantly face a challenge that most industries would envy— the challenge being demand for their products. That demand for frozen food continues to rise as consumers prioritize convenience, flavor preservation, and ease of accessibility. To meet these demands, businesses need innovative, efficient, and scalable solutions to power their unique operations. One exceptional aid to help food producers scale their operations according to their unique requirements is the creation of custom IQF freezer systems from AFE, tailored to the clients’ exact production needs.

Chill Rate Management: How the Quality of Your Control Systems Can Affect Your Bottom Line

November 21, 2024In the food service industry, precision is everything. From ingredient measurements to cook times, every detail can make or break the quality of the final product. But precision doesn’t stop when the cooking does; it’s equally crucial during chilling and freezing. Chill rate management refers to the precise control of how quickly temperatures are reduced in food processing environments, and it is a critical aspect of food production that affects efficiency, product quality, and, ultimately, profitability.

Food Safety Strategy: The Bright Future of Frozen Food Production

October 29, 2024The frozen food industry has undergone a remarkable transformation in recent years, driven by changing consumer preferences and advances in technology. With a growing focus on health, sustainability, and innovation, frozen food production is emerging as a crucial player in the global food landscape. Modern frozen food production, and its ever-expanding technology, has an innovative road ahead, with essentially limitless potential to lead the food production industry toward a sustainable and more secure food system in the immediate future.

Spare Parts Availability: Your Key to Efficient Commercial Refrigeration Maintenance

September 24, 2024In the bustling world of food service, commercial refrigeration units are the silent workhorses that keep your operations running smoothly. Whether you run a restaurant, a grocery store, or a food processing plant, reliable refrigeration is crucial for preserving perishable goods and maintaining food safety standards. However, these vital systems are not immune to wear and tear. When breakdowns occur, the availability of spare parts becomes the linchpin for efficient maintenance and timely repairs.

Blast Freezing: The Means and Method Behind Rapid Temperature Reduction Technology

August 13, 2024Blast freezing is an industrial food preservation process that involves the quick freezing of food (usually in individual portions) through exposure to extremely cold rapidly moving air.

While such products can be frozen for storage in standard industrial freezers, in order to freeze items in a much shorter time—to “flash-freeze” or “blast freeze” them— industry professionals often rely on specially-designed Blast Freezers. Blast Freezers combine a standard freezer’s static temperature reduction ability with enhanced methods (such as blower fan air-exchange technology) to subject products to much colder temperatures, usually through direct application in the form of hyper-cold air. This physical process (commonly referred to by the weather prediction services as “wind chill”) can rapidly lower the temperature of exposed items, freezing them very quickly.

IQF (Individual Quick Freezing): The Effectiveness of Fast Freezing in Food Production

July 17, 2024In today’s fast-paced world, the demand for high-quality, fresh, and convenient food products is at an all-time high. One technology that has significantly impacted the food industry is Individual Quick Freezing, or IQF. This innovative method of freezing not only preserves the freshness and nutritional value of food but also enhances its convenience and safety.

Beef, Pork or Poultry: Hygienic Processing & Quality Preservation

May 23, 2024How Do Spiral and Tunnel Cooling and Freezing Benefit Beef, Pork, or Poultry Processing?

Spiral and tunnel cooling and freezing can make a huge difference in the quality of beef, pork, or poultry processing. Whether you’re a food industry professional or just curious about the science behind food preservation, understanding these methods can shed light on the efficiency and quality of the products we consume.

The Importance of Temperature Control When Processing Vegetables

March 31, 2024Have you ever wondered why temperature control matters when it comes to preserving the freshness of vegetables for the market? If you are involved in commercial food production, that’s a very important consideration. Maintaining precise temperatures during vegetable processing is crucial for preserving product quality and extending shelf life. Temperature fluctuations during the process can accelerate decay, leading to loss of quality and nutrients.