Shake It Off: AFE Shaker Units and How They Work

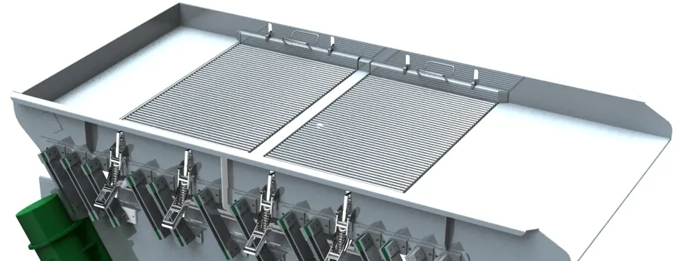

February 26, 2025Shaker units (vibratory conveyors) play an integral role in the industrial food production world. From ensuring product quality to optimizing operational efficiency, these specialized systems are key to handling food products effectively through various stages of the supply chain. At Advanced Food Equipment LLC (AFE), our shaker units are just one of the valuable solutions we provide to maintain seamless food processing, particularly in our Individual Quick Freezing (IQF) systems.

What Are Shaker Units?

Shaker units are specialized vibratory conveyor systems designed to move, distribute, separate, and prepare food items on production lines. By leveraging controlled vibrations, these systems simplify complex processes like transportation, sorting, and grading, ensuring food products are handled meticulously with minimal manual interference.

These units are especially indispensable in IQF freezing systems, where consistency, quality, and speed are essential to product integrity. Using shaker units in these systems helps maintain even product distribution, prevent clumping, and optimize freezer performance.

Why Shaker Units Matter in Food Production

Shaker units are not your average conveyor belts. Their vibratory motion and specialized features go above and beyond basic product transportation to fulfill multiple critical functions:

1. Even Distribution and Spreading

Shaker units distribute food products into a single layer, ensuring they flow evenly onto conveyor lines, such as fluidized bed freezers in IQF systems. This prevents clumping, which is vital for achieving consistent freezing and preserving product quality.

2. Debris and Crumb Removal

Cleanliness is critical in food production, and shaker units with perforated surfaces help remove debris, crumbs, and small particles. This prevents contamination and ensures the final product meets high-quality standards.

3. De-watering and Drying

Dealing with washed or blanched food? Shaker units excel in removing excess water from products like vegetables, seafood, and poultry. Efficient water removal helps prevent ice buildup during freezing and ensures better product stability.

4. Sizing and Grading

Many shaker units are equipped to sort food based on size or weight using various screen openings. This feature allows for the separation of oversized or undersized products, ensuring only optimal pieces move ahead in processing.

5. Consistent Flow Management

Shaker units ensure a controlled and steady flow of food products through the production line, preventing bottlenecks and improving line efficiency. This is particularly essential in high-speed environments like IQF systems.

How Shaker Units Work in IQF Freezing Systems

IQF systems rely heavily on shaker units to maintain uniform product handling before and after freezing. Here’s how shaker units interact with these systems:

- Vibratory Motion: By generating rapid vibrations, shaker units effectively spread food particles evenly across their surface while minimizing damage to fragile items.

- Controlled Velocity: Operators can adjust vibration intensity and speed, ensuring food spreads uniformly before entering IQF freezers.

- Integration with Freezing Equipment: Positioned strategically before and after IQF freezing tunnels, shaker units optimize product preparation, freezing, and post-freezing processes like sorting and packaging.

AFE Shaker Units and Their Versatility

At AFE our shaker units are designed to address multiple food production challenges by meeting the needs of various applications, including transportation, sorting, de-watering, de-fatting, sieving, grading, and more.

Here’s an overview of our shaker units and their unique capabilities:

INDIRECT DRIVEN SHAKERS WITH EPOXY SPRINGS

- Amplitude: Stroke up to 24mm.

- Transport Speed: Up to 800 mm/sec.

- Best For: Continuous product flows, sticky food items.

- Key Features: High amplitude, excellent for challenging product textures, low impact on floors and equipment.

DIRECT DRIVEN SHAKERS WITH ROSTA ELEMENTS

- Amplitude: Stroke up to 8mm.

- Transport Speed: Up to 300 mm/sec.

- Best For: Heavy and continuous product streams.

- Key Features: Reliable and robust for demanding operations.

DIRECT DRIVEN ELECTROMAGNETIC SHAKERS

- Amplitude: Stroke up to 4-5mm.

- Transport Speed: Up to 200 mm/sec.

- Best For: Dosing and feeding.

- Key Features: Start/stop functionality for greater control.

INDIRECT DRIVEN ELECTROMAGNETIC SHAKERS

- Amplitude: Stroke up to 10mm.

- Transport Speed: Up to 500 mm/sec.

- Best For: Discontinuous product flows, dosing, and variable speeds.

- Key Features: Precise control for applications requiring flexibility.

Each shaker model serves a specific purpose, ensuring that businesses of all scales and specialties can find the right fit for their operations.

Applications in Food Processing

AFE shaker units are versatile enough to handle a wide array of food products. Some examples include:

- Fruits and Vegetables: Peas, berries, corn kernels, diced carrots.

- Seafood: Shrimp, scallops, fish fillets.

- Meat and Poultry: Nuggets, diced chicken, bacon bits.

- Grains and Pasta: Pre-cooked frozen pasta, rice.

- Bakery Items: Crumbled toppings, frozen dough pieces.

Regardless of the product, AFE shaker units uphold the highest standards of consistency, quality, and hygiene.

Benefits of Using Shaker Units in IQF Production

Integrating shaker units into your food processing line offers numerous advantages:

- Prevents Product Clumping: Ensures-even separation, essential for IQF products.

- Enhances Quality & Consistency: Achieves uniform freezing and grading.

- Improves Efficiency: Reduces waste and optimizes product handling processes.

- Streamlines Cleaning: Removes unwanted debris and moisture.

- Boosts Freezing Results: Maximizes exposure to cold air for better IQF performance.

Why Choose AFE Shaker Units?

At AFE, we are committed to providing advanced machinery tailored to the dynamic needs of industrial food production. With decades of expertise, our shaker units are designed to integrate seamlessly into complex systems while delivering exceptional value and reliability.

Whether you’re running a sophisticated IQF setup or seeking to improve overall operational efficiency in your production line, AFE shaker units can do the job.

Shake Up Your Production Line Today

Shaker units are more than just an accessory in modern food production—they’re a necessity. From transporting products to optimizing IQF systems, these versatile solutions improve efficiency, ensure quality, and streamline your operations.

Looking to enhance your production capabilities with cutting-edge shaker units? Advanced Food Equipment is here to help. Contact us today to learn more about our solutions and how they can revolutionize your production line.

Get in touch with the AFE team now and experience the next generation of food processing equipment!

Want to revolutionize your food processing operations? Contact us today to discuss the addition of a shaker unit to your system. Together, we’ll turn your ideas into innovation that fuels your growth.